A compact, capable, and supremely transportable concrete batching plant designed for a wide variety of uses and projects within the tunneling and mining industries.

Features

Easy Transport & Assembly

All Eagle plants are pre-wired and pre-plumbed and they can be moved from site to site with standard trucks or stored into containers. All components will either fit on a truck or a shipping container for easy transportation.

Reliability

The Eagle’s excellent reliability rests in its proven engineered construction and a recognized selection of sub suppliers for pneumatic, hydraulic, electrical, drives, and belt componentry. This well-synergized representation of build materials, engineering, and assembly results in a highly reliable product, trusted by concrete producers worldwide. The Eagle plant range and available options make it an ideal fit for precast producers, heavy-civil projects, road construction.

Modular Expansion

“Nexus” aggregate bin structures conveniently bolt a together and collapse for transport with an ability for modification at any time. Modifying the storage configuration by number of aggregates and storage capacity is simple because of the modular design. All Models are available with compartments 12″ – 6″ wide for easy loading by dumper or wheel loader.

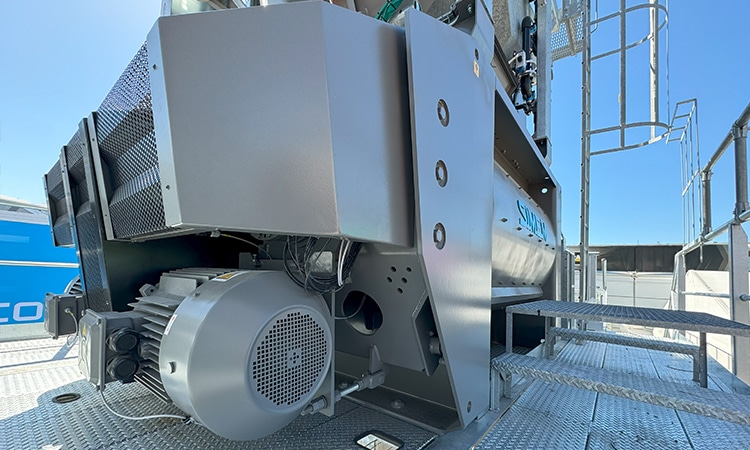

Twin Shaft Mixers

Renowned for durability, longevity, and predictable performance, MSO Mixers are available to serve a range of concrete outputs from 1.5 yd3 to 12 yd3, all suitable for the production of standard wet concrete, SCC, RCC, and MASS (very large aggregate concrete). A combination of heady-duty design, maintenance ease, and wear part hardness lends the lowest maintenance cost per yd3.

Simem@Tic3.0

Simem@tic 3.0 is the automation program with a friendly interface which displays all essential plant operation information. A full process sequence view (loading, weighing, recipe, discharge, washing, production listing, pending orders) with self-adjusting software for a predictable and repeatable outcome. All production data is recorded and stored in SQL database format providing detailed record of concrete production.

Specifications

| Model | 2500 | 4000 | 5000 | 7000 |

| Mixer – Twin Shaft | MSO 2501 | MSO 4001 | MSO 5001 | MSO 7001 |

| Concrete Output m3(cy)/hr | 70 (90) | 100 (130) | 130 (170) | 180 (235) |