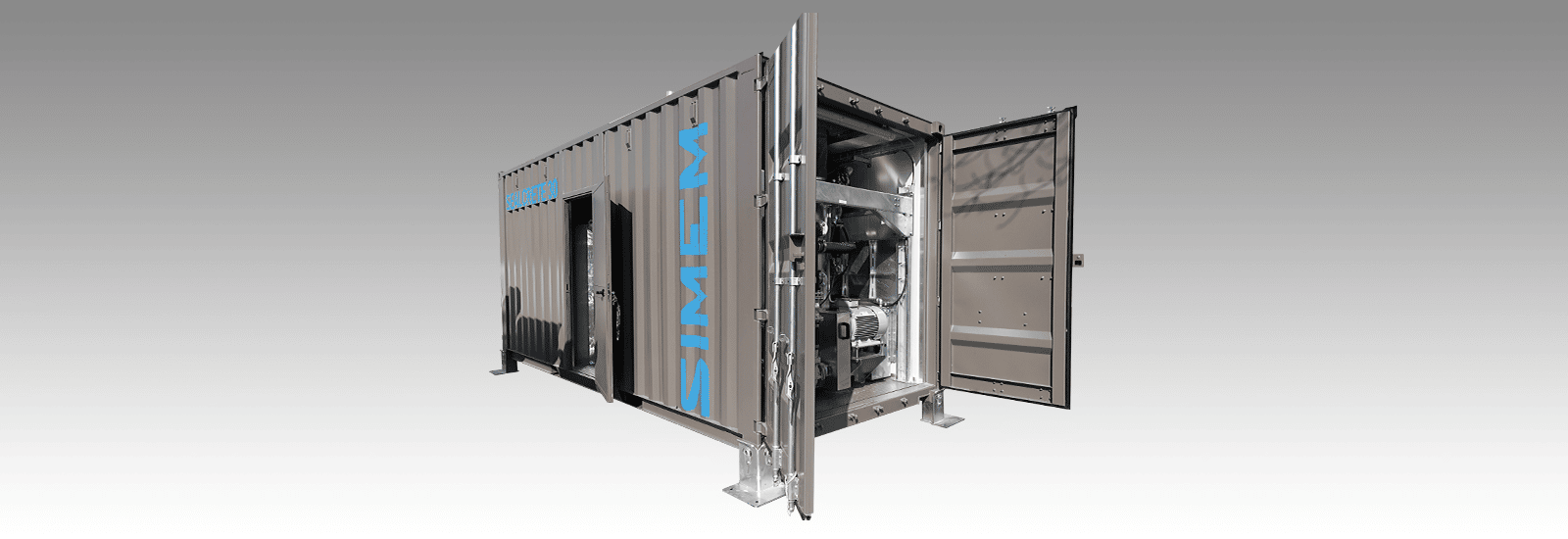

Lightweight cellular concrete is ideal for projects requiring a robust and non-structural material to fill a continuous void or area by pump or bulk delivery. Simem Underground, with decades of mixing, batching, and grout equipment manufacturing experience, specializes in the global design and supply of LDCC containerized grout plants.

What is Lightweight Cellular Concrete?

Low-Density Cellular Concrete (LDCC) is a type of concrete that is lightweight and highly flowable. It is made by mixing cement, water, and preformed foam. The foam creates air cells within the concrete, which increases its volume, reduces its density, and improves its flowability. Mix designs may use fly ash, sand, and other aggregates to achieve specific densities and strengths. LDCC is ideal for a variety of applications due to its properties.

LDCC is produced on-site using a Simem SealCrete containerized grout plant and is pumped into place. A slurry of cement and water is injected with preformed foam and can be pumped substantial distances, making placement easier in confined and/or high-traffic areas.

LDCC offers many unique advantages over traditional engineered fill, including:

- High Strength-To-Weight Ratio

- Customizable Mix Designs

- No Compaction

- Flowability That Eliminates Voids

- Not Affected By Petroleum-Based Products

- Low Maintenance And Easily Excavated

Features

Automatic Foaming Generator

SealCrete LDCC is equipped with an Automatic Foaming Generator (AFG) that includes digital flow meters for both the liquid and air components. This feature allows for easy and accurate measurement of the components.

Pumping Systems

Pumping system design must consider many factors prior to operation. Matching a pumping solution for a specific project application requires extensive knowledge to ensure a pumping system performs as intended. Simem Underground Solutions, and its decades of experience with long-distance pumping of bi-component grouts, cellular concrete, and hydrated bentonite, designs and assembles complete systems guaranteed to perform. System types incorporate piston, peristaltic, progressive cavity, centrifugal, and air-diaphragm pumps. System come complete with associated power control units, instrumentation, and pipe cleaning assemblies. Systems are prepared for field connection as independent components, skid-mounted, or fully containerized.

Combined Contents

SealCrete LDCC combined contents include a VortiMix Colloidal mixer, a high-pressure cleaning system, agitation tanks, pumps, and full automation. These self-contained units are optimized for easy transport, installation, and modular high-output production versatility.