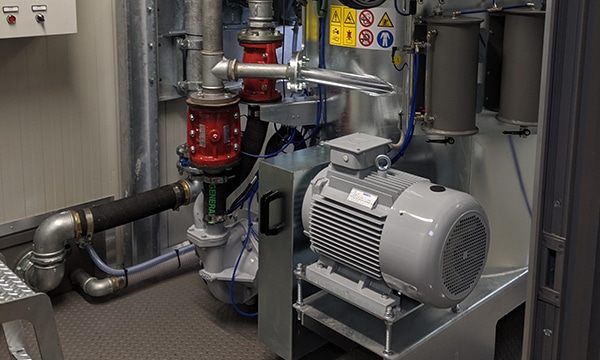

Simem’s SealCrete is a containerized series of grout plants featuring the VortiMix high-shear colloidal mixer. SealCrete’s combined contents includes: VortiMix Colloidal mixer, high pressure cleaning system, agitation tanks, pumps, and full automation. These self-contained units are optimized for easy transport, installation, and modular high-output production versatility.

Features

Application

SealCrete plants are versatile and most popularly used for the production of highly accurate bi-component grouts and hydrated bentonite mixes which support tunnel boring machine (TBM) operations. A SealCrete plant’s ability to produce lightweight cellular concrete, perform jet grouting, deep soil mixing, water cut-off injection, plus slurry wall production – makes it the Swiss Army Knife of solutions.

Auxiliary Equipment

SealCrete plants can be combined with a full range of auxiliary equipment, including containerized liquid storage, agitation tanks, silos, bentonite pre-mixer, foam generators, and skid mounted pumping systems. This range of complete equipment solutions, with standard capacities of 15-50m3/hr. (20-65 yd3/hr.), brings versatility and total cost convenience to underground projects worldwide.

Pumping Systems

Pumping system design must consider many factors prior to operation. Matching a pumping solution for a specific project application requires extensive knowledge to ensure a pumping system performs as intended. Simem Underground Solutions, and its decades of experience with long-distance pumping of bi-component grouts, cellular concrete, and hydrated bentonite, designs and assembles complete systems guaranteed to perform. System types incorporate piston, peristaltic, progressive cavity, centrifugal, and air-diaphragm pumps. System come complete with associated power control units, instrumentation, and pipe cleaning assemblies. Systems are prepared for field connection as independent components, skid-mounted, or fully containerized.