Simem has been recognized worldwide for the wide-range development of mixers, specifically designed for mining applications..

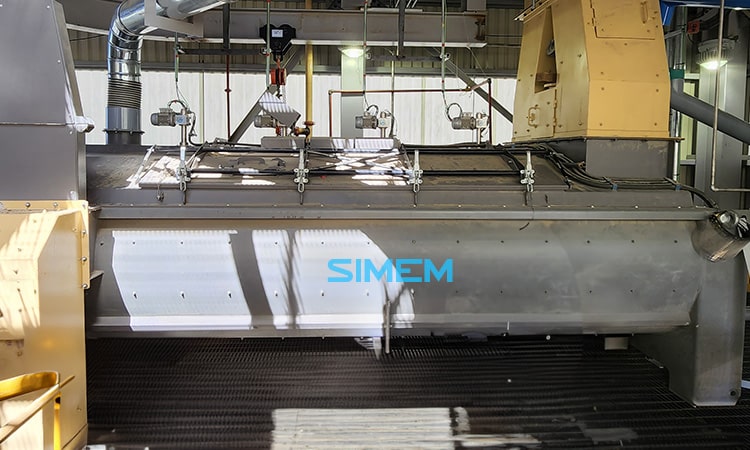

The MDC Continuous Flow Paste Mixer builds upon the already well-recognized twin shaft mixing technology of SIMEM.

With protection wear liners, Ni-Hard cast iron paddles, and hydro-dynamic infused design features to reduce wear, the SIMEM MDC Paste mixer provides an optimal result for the production of Paste backfill.

Features

MDC creates a powerful production capability, providing mining companies with an all-in-one paste production system ideal for mine backfill applications.

With its DUAL-PURPOSE DESIGN, the MDC Twin-Shaft Mixer for mine backfill applications addresses paste production environments that may require a material conditioning process before paste mixing.

The MDC Twin-Shaft Mixer for the production of paste backfill can accommodate tailored discharge points to satisfy a variety of paste plant environments.

94% Efficiency – MixerMindTM Check System

Simem MDC Paste mixers are equipped (as standard) with high efficiency planetary type gearboxes with a mechanical efficiency of up to 94%. Integrated oil cooling systems guarantee a proper working temperature which extends gearbox life and reduces maintenance costs. The MixerMind™ system provides complete surveillance of the mixing operation. The system provides service reminders and alerts upon the detection of abnormalities to avoid potential damages to mixer and its components.

Superwash mixer cleaning system

Simem exclusively designed orbital high pressure rotating wash heads are self-retracting and driven by an independent gearbox and electric motor.

Mixers are treated to a near 3,000 psi cleaning, leaving minimum residual concrete remains in the mixer tank.

More info about the SUPERWASH HERE.

Specifications

MDC – Twin-Shaft Continuous Conditioning Mixer &

MDC – Twin-Shaft Continuous Paste Mixer.

- Mixing tank in carbon steel

- Electric drive with belt driven planetary type gearboxes

- Interconnection between the gearboxes for mechanical synchronization of mixing shafts

- Larger models are equipped as a standard with an oil cooling system

- Lateral and bottom tank liners made of wear resistant steel with a hardness of 450 Brinell (AR 450)

- Mixing arms made of steel, bolted to the shafts, with polyurethane covering

- Mixing paddles made of Ni-Hard cast iron, with a hardness of 600 Brinell

- Safety locks on inspection doors, designed to disconnect the mixing motors (requires interconnection in MCC)

- Water distribution pipe with inlet flange

- Automatic greasing system for shaft seals by electrical pump

- Centralized greasing points for parts subject to normal lubrication

- Temperature sensors on drive motors (PTC) and gearboxes (4-20 mA)

- Pre-wiring to junction box

- Two hydraulic-operated cleanout valves

- Hydraulic power pack

*Discharge options for MDC Paste Mixers

- One bottom discharge or two overflow outlets

| Mixer | Capacity (m3) | Throughput (m3/hr) *Based on 2 – 3-minute retention time |

|---|---|---|

| 201 | 2.4 | 50 – 75 |

| 501 | 3.0 | 60 – 90 |

| 750 | 5.0 | 100 – 150 |

| 1000 | 6.5 | 130 – 195 |

| 1500 | 9.0 | 180 – 270 |

| 2500 | 14 | 280 – 420 |