The high-shear colloidal mill is recognized as the most efficient method of mixing bentonite, cement, fly ash, etc., with water. The intense mixing action results in homogeneous and stable mixes. Colloidally-mixed cementitious products are found to better resist bleed and provide higher compressive strengths than comparable materials prepared in lower energy, paddle-type mixers.

Features

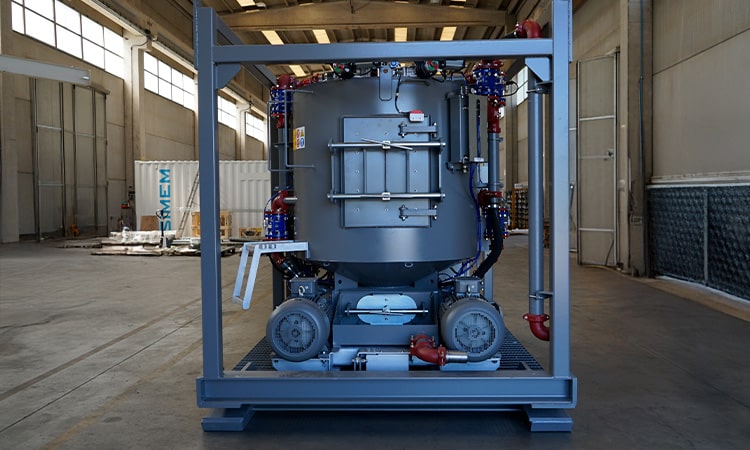

High-Shear Colloidal Mixers

VortiMix is Simem’s new line of advanced high-shear colloidal mixers. The VortiMix can rapidly mix cementitious grouts as low as 0.5:1 water:cement ratio (by weight). When combined with an optional paddle assist, VortiMix can handle grouts as low as 0.45:1 w:c ratio, making the mixer ideal for lightweight cellular concrete applications. Hydrated bentonite can also be rapidly prepared in the VortiMix yielding improved gel strengths and reduced hydration times.

Specifications

| Model | VM500 | VM1000 | VM2000 |

| Batch size l (gal) | 500 (132) | 1000 (264) | 2000 (528) |

| Max. capacity m³(cy)/hr | 7.5 m3/h (9.8 yd3/h) | 15 m3/h (19.6 yd3/h) | 30 m3/h (39.2 yd3/h) |

| Colloidal Mills | One x 22 kW / 30 hp | One x 30 kW / 40 hp | Two x 30 kW / 40 hp |